Manufacturing and industrial systems and software have largely been the Cinderella of the IT industry, being seen as some sort of dark art, with their highly proprietary workings and niche protocols.

Like Cinderella however, this part of the technology industry seems set to get the attention and recognition it deserves, thanks to the cloud and the advent of AI.

We attended this week’s Hexagon LIVE Global customer and partner conference in Las Vegas, to see what the Sweden-headquartered company was doing to help achieve a fairy tale ending for the many industries it serves.

With software, one of Hexagon’s major partners is Microsoft and its Azure cloud. We previously covered a major update to Hexagon’s Metrology measuring software, packed with AI, that is part of the Nexus digital industrial platform.

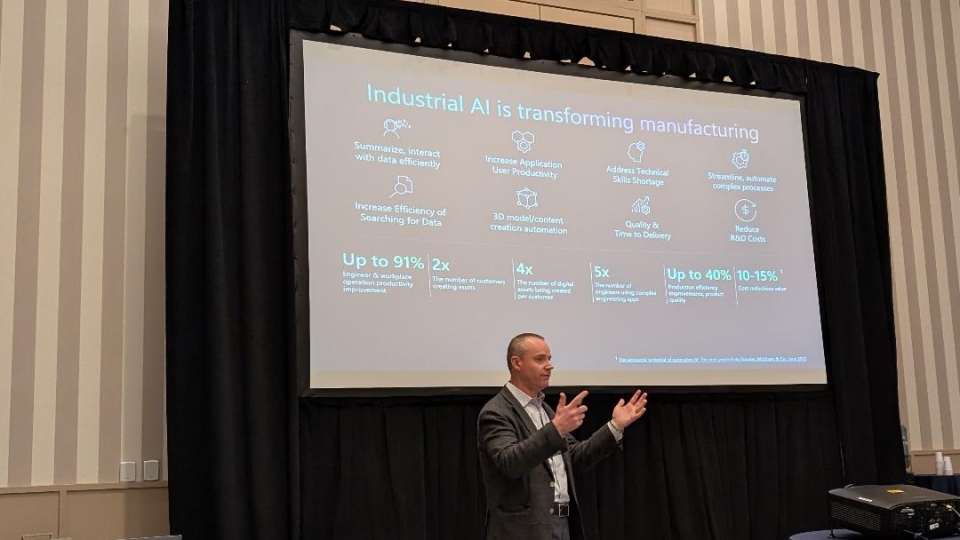

In a breakout presentation to delegates, Guy Bursell (pictured), director of business strategy, manufacturing industry, Microsoft, said: “When it comes to the role of the cloud and AI in the manufacturing partner ecosystem, including Hexagon, it’s about how we interact with the data – structured, unstructured, process-based data, IoT data etc.

“But analyst Gartner, for instance, says manufacturers are making little use of their growing datasets, currently. AI can change this.”

Bursell explained: “There is a skills gap among manufacturers, with ageing staff leaving and a low number of new people with CAD [computer-aided design] skills able to replace them. AI-driven apps can learn over time and grow with you, enabling new CAM [computer-aided manufacturing] staff to move into this area.”

AI-based systems also help to reduce machine costs, said Bursell. He added: “With Azure AI Foundry, we allow partners like Hexagon to experiment with the right models, to enable them to securely deliver the right services that are needed by their customers.”

Stephen Graham, executive vice president, general manager, Nexus, for Hexagon manufacturing intelligence, said of progress in this area: “When we were developing Nexus 3.5 years ago, our cloud experience was limited. But since launching Nexus two years ago, we can now support manufacturers through the entire product lifespan, which is the expertise they need to become more agile.”

He said: “Nexus was a substantial investment for us, and we made sure it could support small- to large-scale deployments, as that is what the industry needed. We have many thousands of users engaged with the technology.”

Graham describes the relationship with Microsoft as “symbiotic”. The end customers use a SaaS model to pay for their Nexus service to Hexagon, and Hexagon pays Microsoft to deliver it to them from its cloud. As more Azure cloud use is generated from Nexus customer growth, Microsoft is keen to promote the platform.

Illustrating the range of products and services the Hexagon group offers, here are some other announcements from the show.

The manufacturing intelligence division unveiled a major update of ESPRIT EDGE, its computer-aided manufacturing (CAM) software. The release introduces advancements in Swiss machining and AI, “empowering” manufacturers to overcome “programming complexity”, and addressing the widening skills gap. It is designed to deliver “enhanced productivity” and “streamlined operations”, to meet the evolving needs of modern, high precision production environments.

ESPRIT EDGE’s Swiss machining functionality is said to enable “safe, efficient and simplified” programming for complex machines such as the CITIZEN L-series and STAR SR-Series. An intelligent digital twin acts as a precise virtual model of the machine, enabling advanced features like superimposition, composite axis control, and automatic prepositioning to optimise performance and “ensure” collision-free operations.

With tools for configuring collets, guide bushings, and tool mounting blocks, ESPRIT EGDE reduces user expertise requirements whilst making set-up faster and more consistent, we are told. Features such as automatic synchronisation, adaptive cycles and tilted plane rotation simplify programming for multi-channel operations, minimising manual coding and errors.

In addition, Hexagon’s safety, infrastructure and geospatial division launched HxGN dC3 Video | Cloud, a new AI-enhanced, cloud-based video management system that enables more agile and resilient surveillance operations.

With the increasing availability of reliable high-bandwidth connections, organisations are adopting a cloud-first strategy and turning to video surveillance as-a-service (VSaaS) for physical security, especially in distributed installations with many sites. The new cloud offering broadens the HxGN dC3 portfolio, Hexagon’s ecosystem of physical security solutions, to provide organisations multiple deployment options and added benefits, such as increased scalability, real-time updates and reduced operating costs, it is promised.

The same division also unveiled Luciad 2025.0, an update to its platform for building advanced location intelligence and real-time situational awareness applications. Luciad 2025.0 delivers improved visualisation and mapping capabilities, and greater control over defence and intelligence data.

Users and developers now have more flexibility for handling National Imagery Transmission Format (NITF) data, the mandated standard for packaging and sharing digital imagery and associated intelligence data among US defence and intelligence organisations. LuciadFusion and LuciadLightspeed upgrades enable non-georeferenced and georeferenced views, enhancing NITF data interpretation and the handling of images and vector overlays, with LuciadFusion also allowing browser-based viewing.